|

|

|

||

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

に名称が変わりました .  |

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

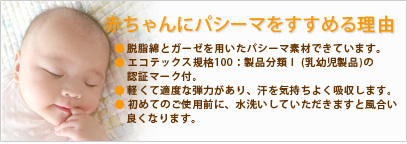

①原綿/原綿は弾力があり、繊維の長いものを厳選。②混打綿〜③梳綿/原綿中の茎や葉を取り除きムラのない厚みに揃えます。④製織〜⑤合体/タオルよりも細い綿糸でガーゼを織り、中綿と合わせます。⑥精練・漂白・染色/綿花の純度を上げる精練から染色を2日間かけて仕上げます。⑦乾燥/熱風で乾燥させ、温度・硬さ・吸水性のチェックも行います。⑧キルティング/通常より針目が約2倍の細かさ。自社マシンで細かく縫い合わせます。⑨裁断・縫製/製品形状に加工します。裁断後すぐに縫製しています。⑩検品・袋詰め/異物、目とび、シワなどの品質チェック後に袋詰めします。⑪検針・箱詰め〜⑫出荷/異物混入を検針器でチェックし、鉄以外の金属も確認してから出荷。一品ずつバーコードで管理しています。 The process of making pasima 1) Raw cotton:Raw cotton with long, elastic fibers is carefully selected. 2) Mixing/ blowing - 3) Carding: Stalks and leaves are removed from the raw cotton and made to a uniform thickness. 4) Weaving - 5) Coalescing: Gauze is woven with fibers finer then those used in towels and joined to the inner cotton. 6) Scouring/ Bleaching/ Dyeing: 2day process of purifying and dyeing to raise the purity of the raw cotton. 7) Drying: Blowing while monitoring the temperature, stiffness and absorption. 8) Quilting: stitching twice as fine as normal. Our own sewing machines sew a finer seam. 9) Cutting/ Sewing: Products made to the desired shape. Sewing straight after cutting. 10) Inspection/ Packaging: Products are packaged after quality control inspection for foreign objects, skipped stitches and wrinkles. 11) Needle inspection/ Boxing - 12) Dispatch: Check for foreign objects with needle inspection machine, and check for metals other than iron before dispatch. Each item is managed by an individual barcode. |

|||||||||||||||||||||||||||||||||||

| Chromeブラウザでの文字表示のズレについて。 文字が小さくて読めない場合は、ブラウザのズーム機能([Ctrl]+[+]/[-]で拡大/縮小)をご利用ください。 |

|||||||||||||||||||||||||||||||||||

おかげさまで創業159周年

西川・マニフレックス 取扱店

株式会社山田ふとん店 店長 山田康博

〒515-0085 三重県松阪市湊町197

TEL:0598-21-0539 FAX:0598-21-0573

フリーダイヤル:0120-89-0539

All Rights Reserved, Copyright(C) 2022 YAMADA-FUTON Co.,Ltd.

西川・マニフレックス 取扱店

株式会社山田ふとん店 店長 山田康博

〒515-0085 三重県松阪市湊町197

TEL:0598-21-0539 FAX:0598-21-0573

フリーダイヤル:0120-89-0539

All Rights Reserved, Copyright(C) 2022 YAMADA-FUTON Co.,Ltd.